Work With Us

FT Precision (FTP) understands the challenges manufacturers and buyers face to assure the integrity of their lines. Choosing a supplier who can meet volume, fulfill or exceed product specifications and provide the resources that guarantee production and delivery are vital priorities, and perhaps just the beginning of decisions that will identify a unique and valued client-vendor relationship.

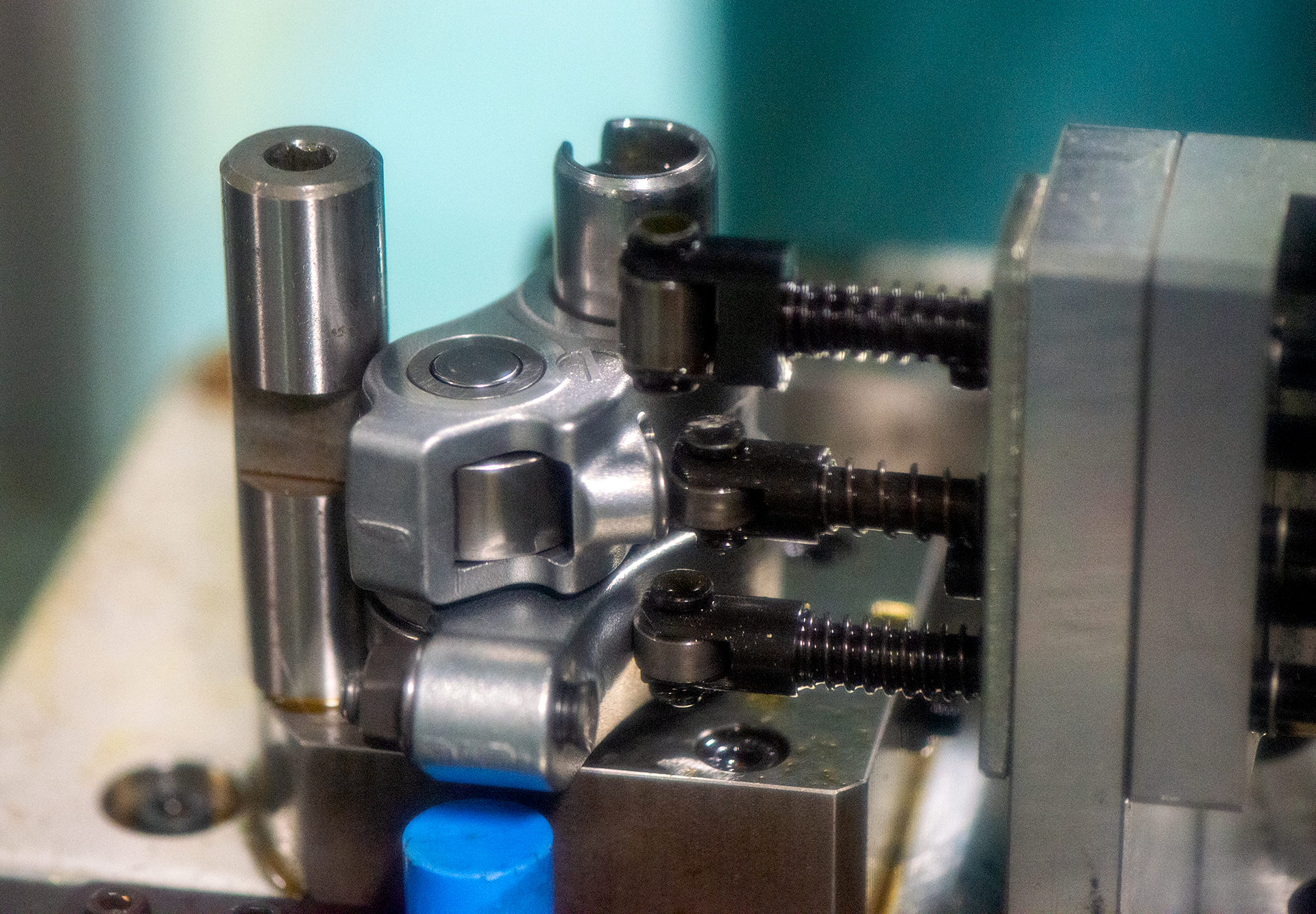

FTP is here to provide for customers with the most responsive, reliable resources available for precision parts manufacture and delivery. Our manufacturing platform and expertise offer exceptional capability to fulfill production demands and keep your assembly lines flowing smoothly and productively.

Our Customers

Building Strong Partnerships for Success

Whatever your industry or production needs may be, FTP welcomes the opportunity to meet with you, and with dedicated purpose on your behalf. Our manufacturing capacity, along with the full compliment of resources available through our associate Tanaka Group companies, affords us great flexibility to address diverse customer needs.

Core Attributes

- Ability to meet required volume and relationship demands (open door policy, transparency, willingness for long-term investment) and possession of resources to guarantee production.

- Mass production volume at designated level of precision and accuracy (e.g., 10,000 parts per day at pitch +-15 um with low NG rate)

- Award-winning Quality & Delivery track record and expertise in reliable production.

- Quantity and diversity of machining (i.e. CNC/Robodrill) for mass production at precision levels. Example: Niche utilization of 250 & 300 ton die cast machines to create higher quality, lower cost parts.