Aluminum Die Casting × High-Precision Machining × Integrated Production

Our signature product, the rocker arm, is a high-precision functional component designed to unlock the full performance potential of modern engines.

We combine micron-level precision control with decades of machining expertise to deliver components with world-class reliability.

With a fully integrated in-house production system and advanced automation lines, we provide flexible, efficient manufacturing solutions—from small-batch, high-mix orders to full-scale mass production.

Our streamlined operations are built to respond quickly and accurately to the evolving needs of our customers.

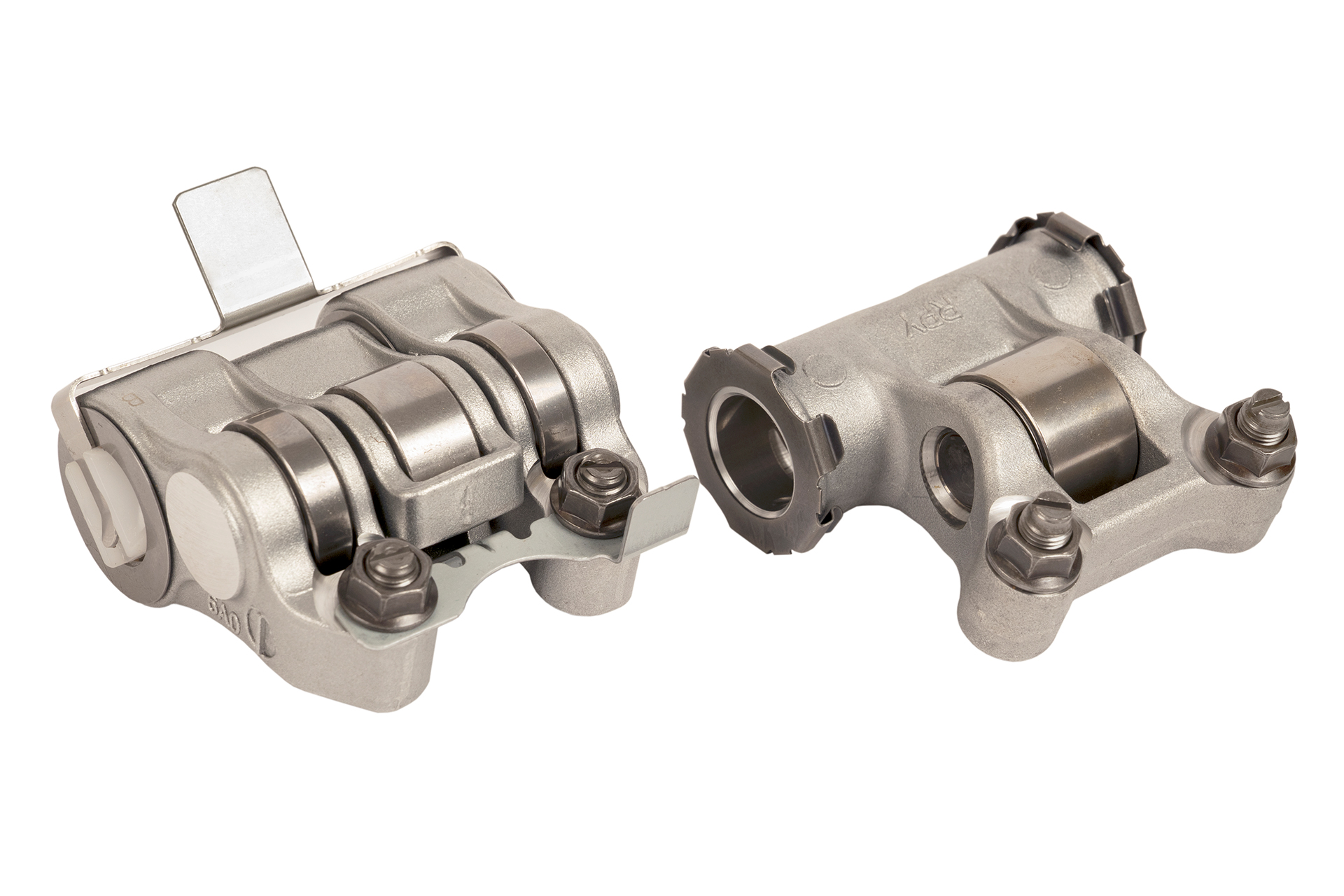

Rocker Arm

Equipment Capacity: 250~350t

Material: HD2G, DH3

Process: HPDC, Machining, assembly

Water Passage

Equipment Capacity: 350t

Material: HD2G

Process: HPDC, Machining, assembly

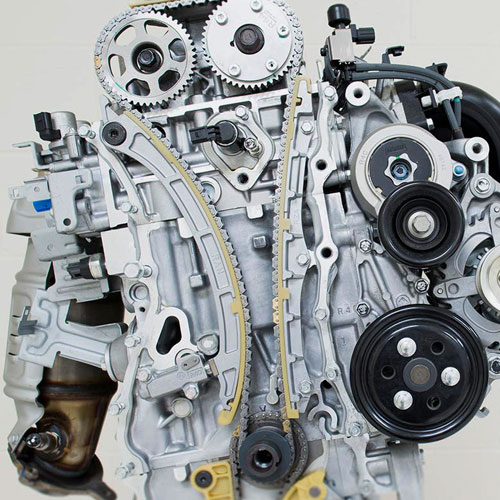

Sub-arm Tensioner

Equipment Capacity: 350t

Material: HD2G

Process: HPDC, Machining, assembly

Engine mount

Equipment Capacity: 350t~650t

Material: HD2G, ADC12

Process: HPDC, Machining

Breather Baffle

Equipment Capacity: 350t

Material: HD2G

Process: HPDC, Machining, assembly